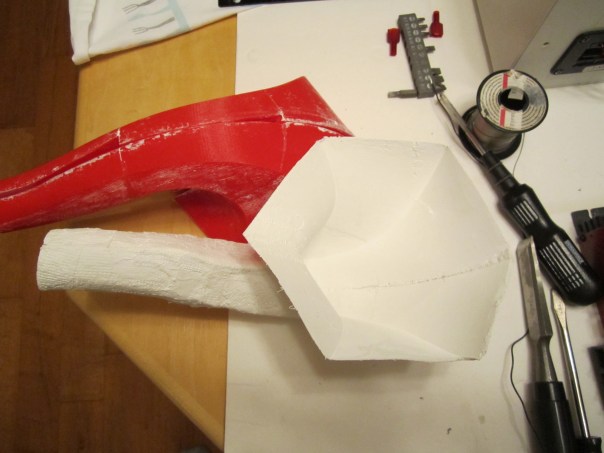

Each half of the horn sections are 3-D printed in three sections… at over 12 inches in height and hollow, each section took about 4 hours to print.

Left and right halves… I used plastic glue for regular models to glue the sections together.

Not perfect but I was able to create my largest print to date from my 3D printer.

Using the plastic molds I was able to use a casting material with the feel of a cast to set a bone break. I found a small package of it at Hobbie Lobby for around 10 bucks. Stiff and ridged when dry, but I was able to get all of the contours of the horn.

You can see the seem in the center where the two halves came together to make the full horn.

Using a full range 5 inch speaker, MDF board cutting a cube of 7 inch by 7 inch by 7 inch the speaker box was completed… the Pair then had a small 1 1/4 inch hole cut into the center top of the speaker box…. this allows the frequencies to transfer to the horn, amplifing the voice and mid range frequencies nicely.

Side view of the left speaker… and detail.

The Right speaker box.

Front view… I will try and post a link to a Youtube recording once I get the final mount for the horn completed and get a good recording of a voice or a horn section.