One of my friends had a mixer his mother used for many years and he wanted to get it running again after it stopped working. Knowing I like a challenge and like to fix things he asked me if I could look at it and get it running again.

Tearing it down since I had no idea if it had been taken apart or if it was all there I discover a really well built mixer…

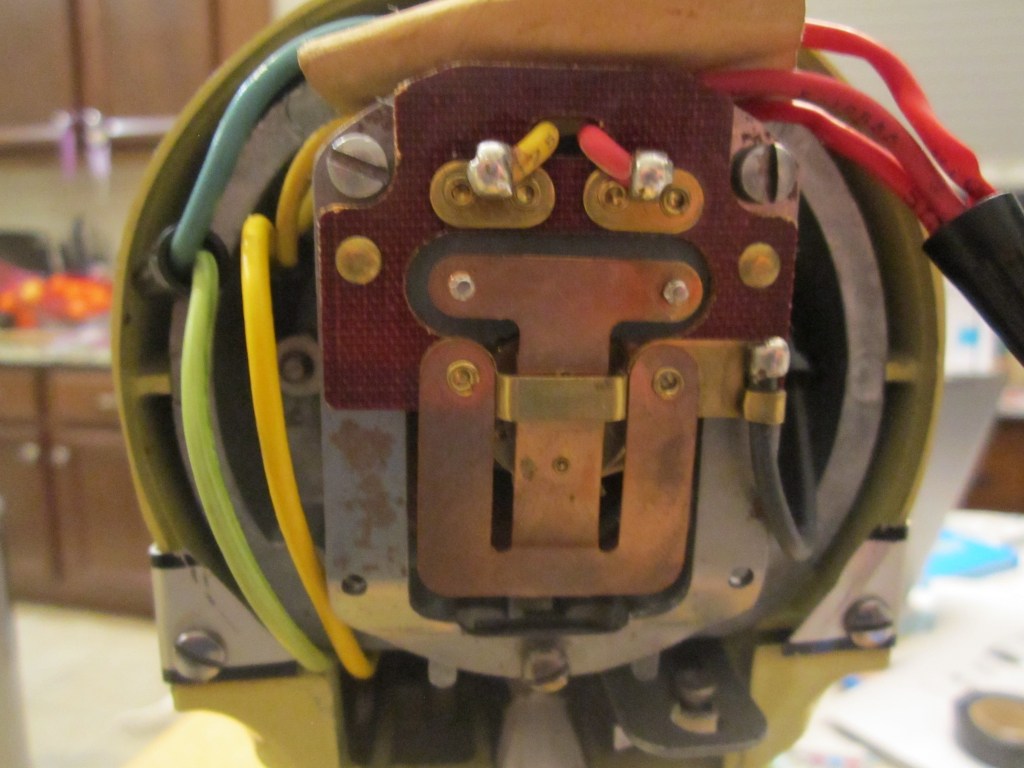

Electrical had a wire that had fallen out of the wire nut… I soldered the connections and taped them off, not the cleanest, but it made sure they won’t come apart.

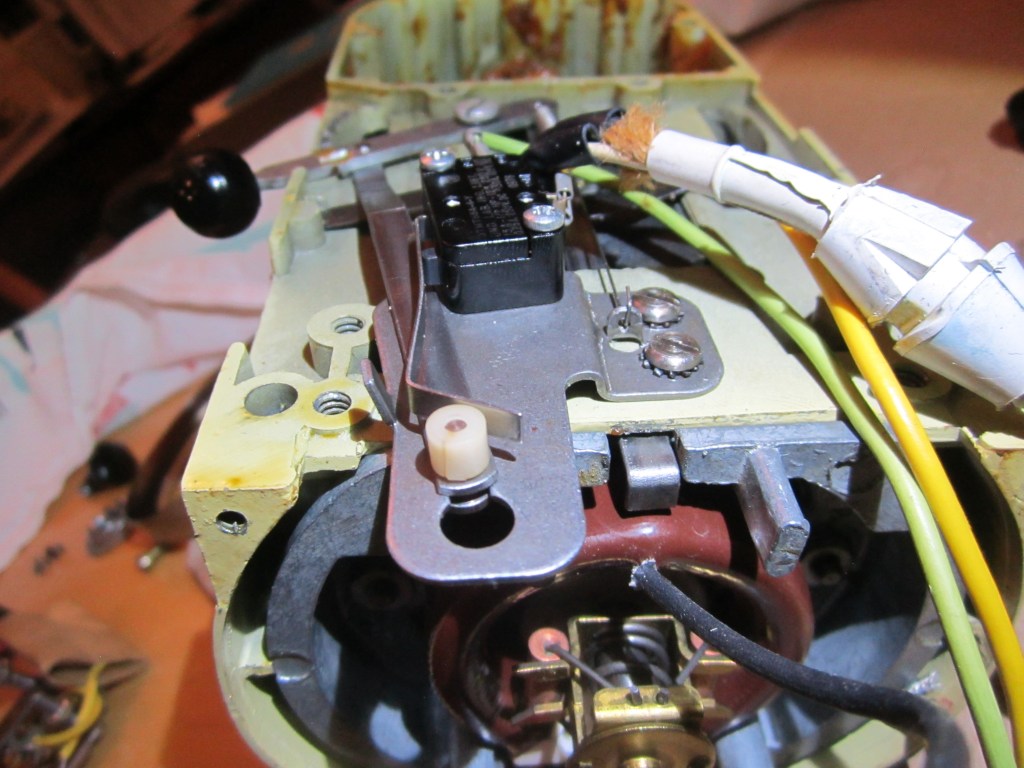

Old grease and clean up of the old grease will definitely reduce the load on the motor.

So after cleaning, fixing the stator brush: ‘A carbon brush, also known as a motor brush, is the small part of the motor that conducts electrical current between the stationary wires (stator) and the rotating wires (rotor) of a motor or generator. ‘

And of course making sure all the wires were soldered together, a quick plug into the GFI outlet, a flick of the power lever, a soft smell of ozone after arcing the motor…. the mixer came alive!

This was one of the first things I look for when repairing old electronics is the power switch and the contacts… some get worn out, due to arcing and a build up of carbon deposits, if you can see the pads, you can clean them, but in this case it is a sealed switch. Sometime there is a mechanical interface issue, (which was in this case) or sometimes the switch is just broken.

Hello mate great bllog