For a long time I have been very interested in building speakers… for home, for stage, for car and for outdoors… I have tried many different styles and types of enclosures… but I came home from work and looking around in my garage I decided to build a very quick bass tube out of free junk I have collected. i have always wanted to try this type of tube style with the extra added horn/port… and i figured I would capture some photos along the way to show the build.

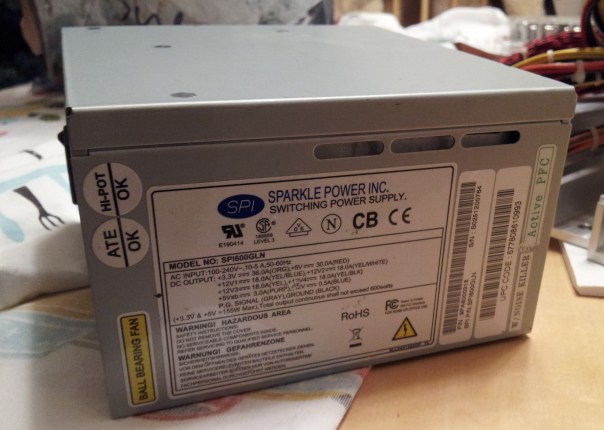

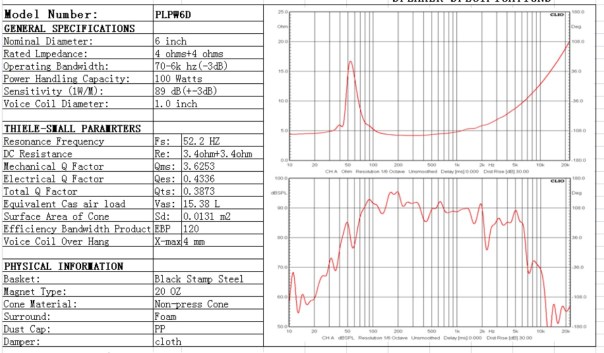

I did some very basic calculations to find the perfect length and using the data sheet for the speaker (a Pyle Power Series Dual Voice-Coil 4-Ohm 6.5-inch 600-Watt Subwoofer) I optimized the volume for the 40 to 50 Hz frequency. Now the spec for the speakers says the range is 38 to 70 Hz, but the port will be tuned for 53 Hz.

Some plastic tube and a cardboard tube (all free) will become the body, some scrap particle board will hold the speaker at one end and the other end the speaker connection. Some blanket matting will become the interior tube baffle or damping material, and some wire will be run the length to ensure I have good connections to the speaker (once it arrives in the mail).

Plastic tube is cut to the correct length which is based on the volume needed for a ported enclosure.. in my case it was 27 inches.

Here is the peices cut… the ends have a flat edge to keep the speaker from rolling around.

Some glued in matting… a dry assembly and now to put it all together. (Right photo: Looking down the tube cut in half to make the port.)

I just used some construction adhesive to join everything… since it is ported I am thinking the pressure will be minimal and not fatigue all of the parts connection points. I might run a few drywall screws in key locations just to be safe before I cover the tube. HEY! There is the Stuka! My 1968 BMW 2002 in the garage for the winter taking a nap and on the trickle charger!

For now… I will let it dry and wait for the speaker to arrive… once I get the woofer I will finish the build, conduct a measurement recording of a sweep frequency of 20 Hz to 70Hz and plot the data for a review and blog post. I hope to have it done soon!